Latest PCB Technology: Trends, Innovations & What’s Next

In the rapidly evolving electronics landscape, printed circuit board (PCB) technology continues to drive innovation. From high-speed communications to wearable devices, PCBs are at the heart of nearly every modern electronic product. In this article, we explore the latest trends in PCB tech, what innovations are shaping the future, and what companies/arise need to know to stay ahead.

What Has Evolves So Far

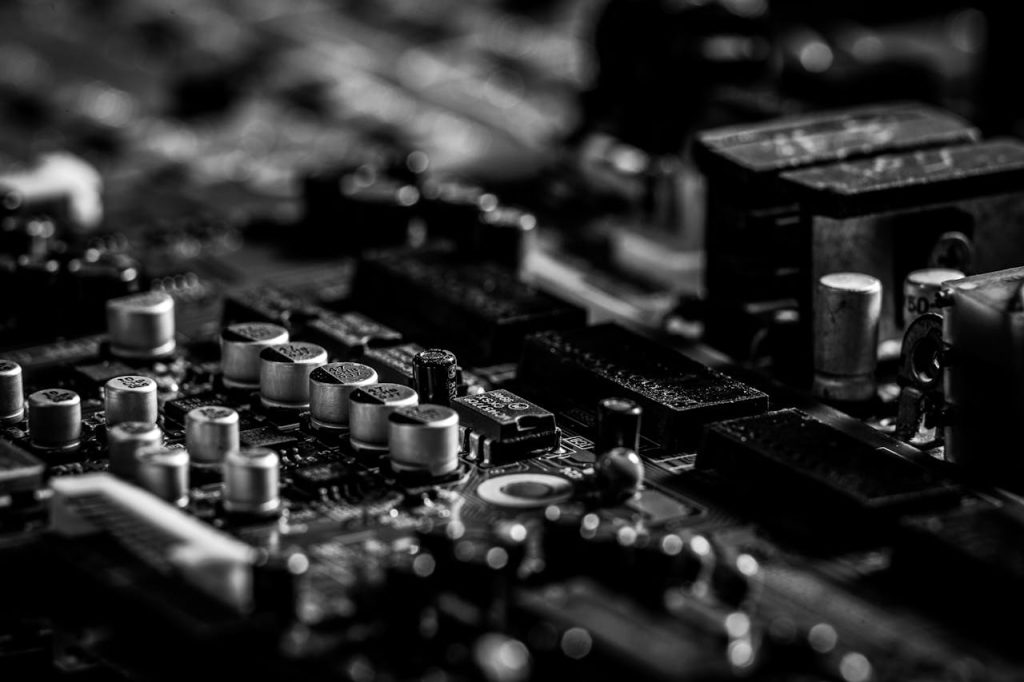

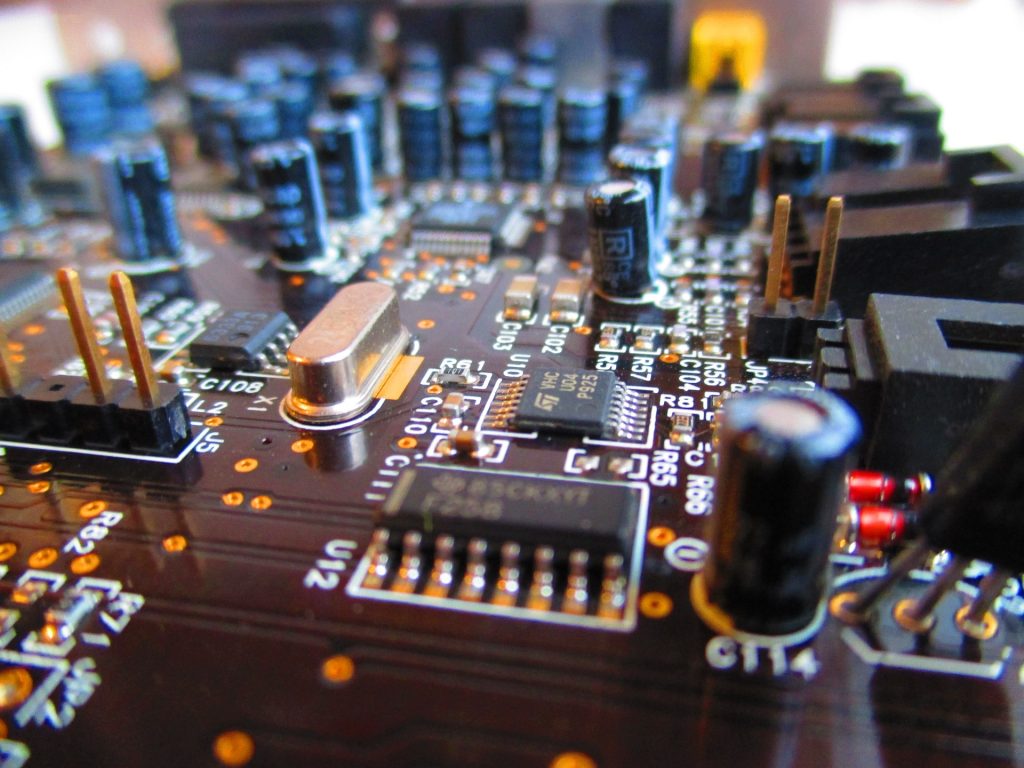

To understand the present, it helps to look back. Early PCBs were rigid, single-sided or double-sided boards using simple plated through-holes (PTH). Over time, multilayer boards, surface-mount technology (SMT), then high-density interconnect (HDI) have become standard.

More recent developments include rigid-flex boards, thicker copper plating for power applications, boards made for RF/microwave applications, and special materials (like Rogers, aluminum cores, ceramics) to meet high-frequency, high-thermal or harsh-environment requirements.

Key Trends & Breakthroughs in Modern PCB Technology

Here are the cutting-edge trends that are transforming PCB design, fabrication, and application:

1. High-Frequency, High-Speed PCBs

As 5G/6G, IoT, and high-speed digital electronics proliferate, demands for PCBs that support higher signal frequencies are growing. What this means: lower dielectric loss, tighter tolerances for trace width and spacing, and better material choices.

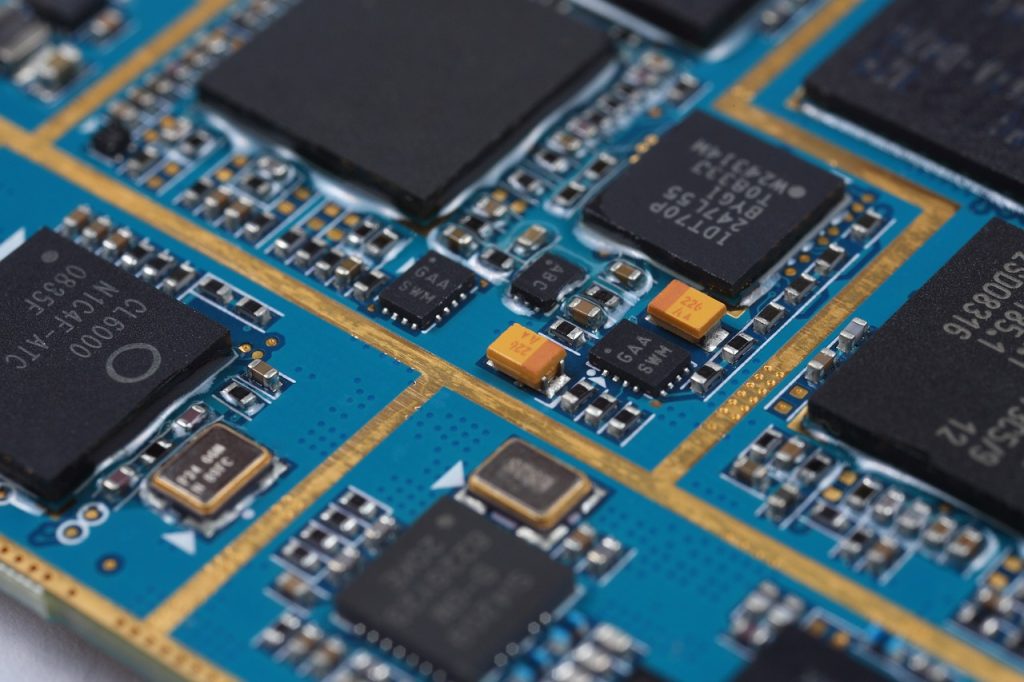

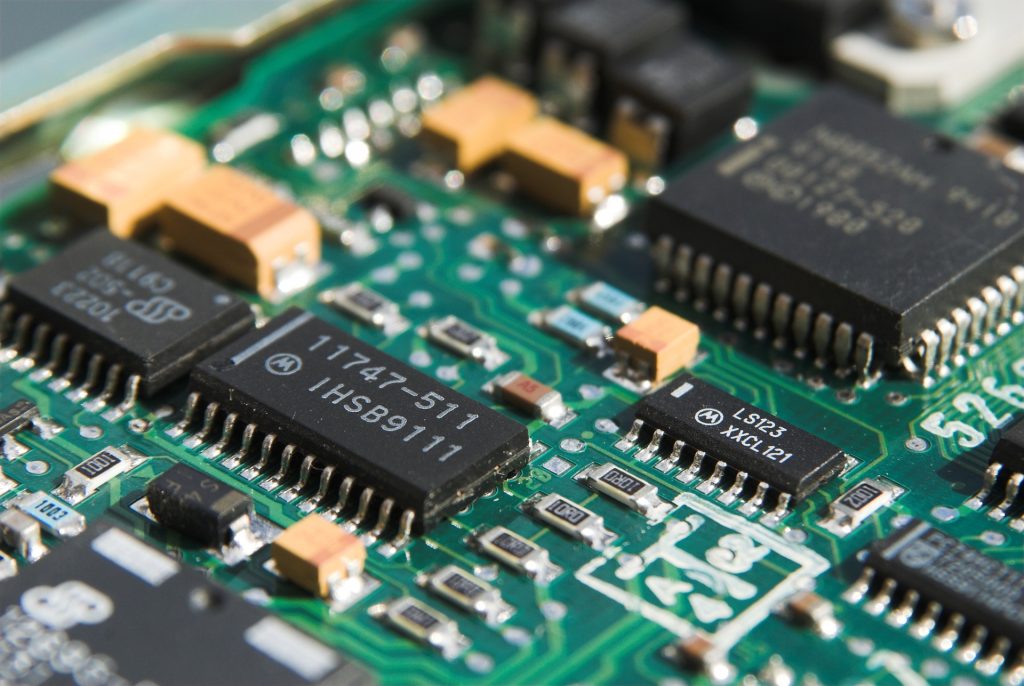

2. Multilayer & HDI (High Density Interconnect)

More layers allow more complex routing, reduce board size, and support more functionality. HDI—including buried vias, blind vias, microvias—is now essential for mobile, wearable, and compact devices.

3. Rigid-Flex & Flexible PCBs

To get around mechanical constraints, bending, or fitting PCBs into odd shapes, rigid-flex and fully flexible boards are increasingly common. They reduce connectors, save space, and often improve reliability in applications where the board must flex or fold.

The substrate and dielectric materials are improving: higher Tg (glass transition temperature), lower coefficient of thermal expansion (CTE), higher thermal conductivity, and materials optimized for high-frequency performance are in demand. Metal cores, ceramic bases, or hybrid materials are getting more used.

5. Embedded / Inserted Components

Embedding passive or even active components within substrate layers (rather than surface mounting everything) helps reduce size, improve electrical performance (less parasitic capacitance/inductance), and improve thermal behavior.

6. 3D Printing and Additive Manufacturing

It’s a newer area, but additive techniques for PCB production (printing conductive traces, using printable substrates, etc.) are showing potential especially for rapid prototyping or custom, low-volume production.

7. Better Imaging and Precision Techniques

Techniques such as Laser Direct Imaging (LDI) are replacing older mask-based methods. This improves resolution, reduces defects, and allows finer features needed for HDI and high-frequency boards.

8. Soldering and Assembly Innovations

Innovations in soldering (laser soldering, selective soldering), surface finishes (lead-free, ENIG, etc.), and more precise assembly help ensure reliability in smaller components, mixed technology boards, and in environments with thermal stress.

9. Sustainability / Eco-friendly PCB Solutions

Cutting down waste, reducing copper usage, using more environmentally friendly materials, and improving recyclability are rising priorities. A recent example is Elephantech’s SustainaCircuits™ technology, which aims to reduce copper usage by ~70-80% while being multilayer and rigid-substrate compatible.

Applications Driving Demand

These innovations are not happening in a vacuum. Key industries are pushing the envelope, requiring more from PCB tech:

- Telecommunications & 5G/6G: High frequency performance, low loss, HDI, RF-specific substrates.

- Automotive & Electric Vehicles: Thermal management, high-power handling, reliability under vibration & temperature extremes.

- Medical & Wearables: Miniaturization, flexible/rigid-flex PCBs, biocompatibility (sometimes), high reliability.

- Aerospace / Defense: Mission-critical reliability, extreme environment operation, often needing certifications.

- IoT & Consumer Electronics: Compact size, low cost, flexible form factors, high speed but also mass production.

Challenges and What’s Holding Back Faster Adoption

While there’s much promise, several hurdles remain:

- Cost: High-performance materials, specialized equipment (for microvias, LDI, flexible substrates) cost more.

- Manufacturing complexity: As boards get more dense / multilayer / embedded parts, fabrication and assembly steps become more intricate, increasing risk of defects.

- Reliability under stress: Thermal cycling, mechanical flex, moisture, etc., can degrade designs if not properly engineered.

- Supply chain and materials availability: Some advanced materials are harder to source, or have long lead times.

- Skill & design constraints: Designers must have experience with high-speed layout, signal integrity, thermal management, etc. Not all teams are ready.

What PCB Manufacturers & Designers Should Do

To stay at the cutting edge, here’s what companies and engineers should consider:

- Invest in new fabrication tools for microvia drilling, laser imaging, accurate multilayer lamination, rigid-flex capability.

- Material R&D / qualification to find substrates with better performance (thermal, electrical, mechanical) that are also cost-effective.

- Design for manufacturability (DfM) & Design for reliability (DfR): from the layout stage, think about how signal integrity, thermal stresses, and assembly yield will affect end product.

- Environmentally conscious design: reducing material waste, using recyclable materials, minimizing copper usage, considering lifecycle impacts.

- Collaboration & standardization: As industries (automotive, medical, telecom) require certifications and high reliability, following standards (IPC, ISO, etc.) and collaborating across the supply chain helps.

- Prototyping and simulation: using simulations (thermal, signal, mechanical), prototype runs, and quality testing early helps catch issues before scaling up.

What’s Coming: The Next Frontiers

Looking ahead, some of the exciting innovations likely to shape PCB technology are:

- Printed Light Boards (PLBs): Combining lighting or optical elements directly into boards.

- More widespread use of additive manufacturing and printed electronics, possibly even replacing copper traces in certain applications.

- Higher layer counts and stack-ups with more complex via topologies (buried, blind, micro-vias, etc.) to pack more functions in less space.

- Smart / adaptive PCBs: Boards that can self-monitor (temperature, stress) or adapt performance.

- Material science breakthroughs: composites, nanomaterials, substrates with ultra-low loss for RF, better thermal dissipation.

Latest PCB Technology: Trends, Innovations & What’s Next Read More »