Industry 4.0

“Industry 4.0” refers to the fourth industrial revolution. After mechanization (Industry 1.0), mass production (Industry 2.0), and automation (Industry 3.0), now the “internet of things and services’ is becoming an integral part of manufacturing. Industry 4.0 technologies have the potential to create extraordinary growth opportunities and competitive advantages for Germany as a business location. Experts forecast that businesses will be able to increase their productivity by about 30 percent using Industry 4.0’’ – BDI The Voice of German Industry

“INDUSTRIE 4.0 connects embedded system production technologies and smart production processes to pave the way to a new technological age which will radically transform industry and production value chains and business models.’’ – Germany Trade and Invest

Embracing Industry 4.0 – and Rediscovering Growth

“What is existing manufacturing and large technological innovations coming together to create the next big manufacturing reinvention? Bingo. This is the fourth manufacturing revolution, and it’s happening right now.” – OLIVIER SCALABRE Senior Partner & Managing Director Paris

The rise of new digital industrial technology, known as Industry 4.0, is a transformation that makes it possible to gather and analyze data across machines, enabling faster, more flexible, and more efficient processes to produce higher-quality goods at reduced costs. This manufacturing revolution will increase productivity, shift economics, foster industrial growth, and modify the profile of the workforce—ultimately changing the competitiveness of companies and regions.

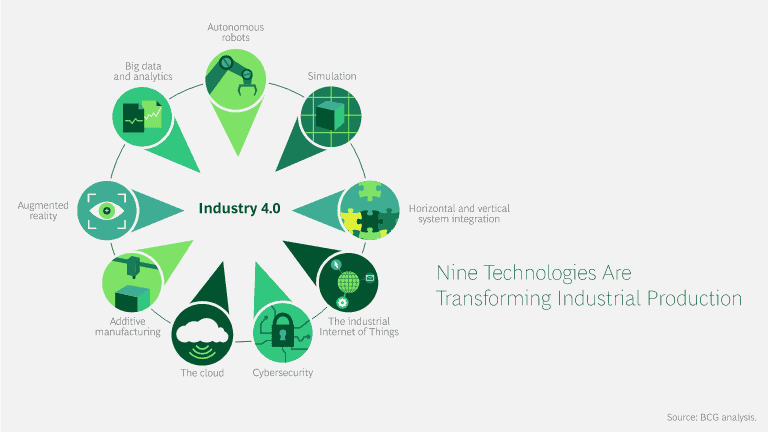

Nine Technologies Transforming Industrial Production

Advanced digital technology is already used in manufacturing, but Industry 4.0 will transform production. It will lead to greater efficiencies and change traditional production relationships among suppliers, producers, and customers—as well as between humans and machines. Nine technology trends form the building blocks of Industry 4.0.

Adopting Industry 4.0

Companies face formidable challenges in the adoption of these new technologies. To build and sustain a lead in the race to full implementation, they need to broaden and deepen their practical knowledge about digital technologies and the related use cases—and then develop and implement tailored digital manufacturing strategies.

BCG’s approach to Industry 4.0—along with the firm’s state-of-the-art model factories, or Innovation Centers for Operations—provides companies with the support they need to master the challenges of implementation.